Researchers are expanding new miniature camera technology for military and security uses so soldiers can track combatants in dark caves or urban alleys, and security officials can unobtrusively identify a subject from an iris scan.

Researchers are expanding new miniature camera technology for military and security uses so soldiers can track combatants in dark caves or urban alleys, and security officials can unobtrusively identify a subject from an iris scan.

The two new surveillance applications both build on “Panoptes,” a platform technology developed under a project led by Marc Christensen at Southern Methodist University in Dallas and funded by the Department of Defense.

Panoptes is a compact, lightweight, high-resolution smart camera that is named for the Greek mythological character Argos Panoptes, the giant sentry with a hundred eyes.

DOD is funding development of the technology’s first two extension applications with a $1.6 million grant to SMU.

|

| Wired: DARPA’s Beady-Eyed Camera Spots the ‘Non-Cooperative’ |

Both the tiny cave camera and the iris recognition application will aid the military, border patrol, intelligence officials and airport security, according to Christensen and Delores Etter, a leading researcher in biometric identification.

Both are electrical engineers in SMU’s Bobby B. Lyle School of Engineering. The new applications may be ready for fielded demonstrations as soon as late 2011, said Christensen.

The Panoptes imaging system has been field-tested in tactical environment simulations by defense contractor Northrop Grumman and is currently in an independent test with Draper Laboratory.

“The Panoptes technology is sufficiently mature that it can now leave our lab, and we’re finding lots of applications for it,” said Christensen, an expert in computational imaging and optical interconnections. “This new money will allow us to explore Panoptes’ use for non-cooperative iris recognition systems for Homeland Security and other defense applications. And it will allow us to enhance the camera system to make it capable of active illumination so it can travel into dark places — like caves and urban areas.”

The new grant brings total DOD funding of Panoptes — short for “Processing Arrays of Nyquist-limited Observations to Produce a Thin Electro-optic Sensor” — to $5.5 million. The new applications have been dubbed AIM-CAMS, for “Active Illumination with Micro-mirror-arrays for Computational Adaptive Multi-resolution Sensing,” and Smart-Iris, for “SMU’s Multi-resolution Adaptive Roving Task-specific Iris Recognition Imaging System.”

Hi-rez “eyes” in caves, urban alleys

Panoptes initially was designed for military aerial drones and combat helmet cameras for use in daylight environments. The technology produces sharp, clear images without the size and weight of a conventional camera system because it doesn’t rely on a large, bulky, curved lens for high-resolution images.

Panoptes initially was designed for military aerial drones and combat helmet cameras for use in daylight environments. The technology produces sharp, clear images without the size and weight of a conventional camera system because it doesn’t rely on a large, bulky, curved lens for high-resolution images.

Instead, arrays of agile and precisely controlled microelectromechanical system (MEMS) mirrors are integrated with low-resolution sub-imagers on a silicon base for the purpose of sampling a wide field of view. The analog steerable MEMS mirrors adaptively redirect plexiglas sub-imagers to zoom in on regions of interest. The captured images are stored in an onboard computer and restored to high-resolution by an information theory-based super-resolution algorithm.

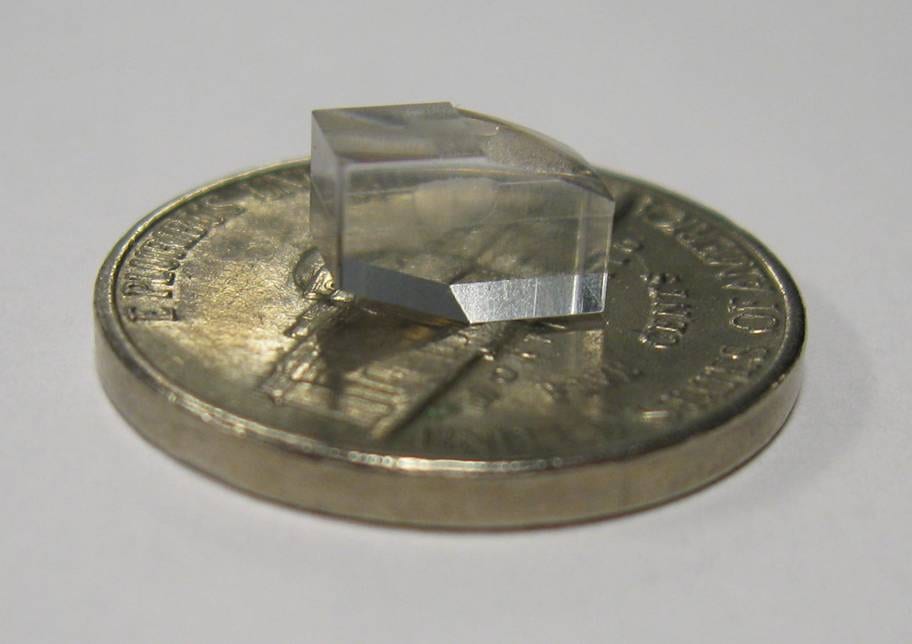

The sub-imagers are tiny off-axis-shaped paraboloids, fabricated using injection molding. At 8 millimeters by 5.7 millimeters by 4 millimeters, the sub-imagers have an effective focal length of 4 millimeters and are tiny enough to fit on the surface of a small coin.

The honeycomb-shaped micro mirror array comprises 61 hexagonal mirrors, each with three actuators to mechanically move and control the mirrors. The usable circular aperture, the opening through which light travels, is 3.9 millimeters in diameter. The end result — a digitally restored image — while not super-resolution, approaches optical limit, the researchers say.

The flat sub-imagers can be tiled unobtrusively almost anywhere, from the underside of a small drone to the outside of a soldier’s helmet to the walls of a hallway.

The Panoptes architecture is unique in its ability to adapt its field of view to steer to a region of interest, capturing only images of value, Christensen said. That preserves computing power by eliminating uniform allocation of imaging resources, which is wasteful, he said.

Smart-Iris narrows from wide field-of-view to narrow field-of-view

To develop the biometric Smart-Iris, the adaptive resolution of Panoptes will be paired with iris recognition technology.

“It’s very challenging to get the resolution with a wide field-of-view camera, but with a zoom camera, it’s hard to find the iris because it’s like looking through a soda straw,” Christensen said.

|

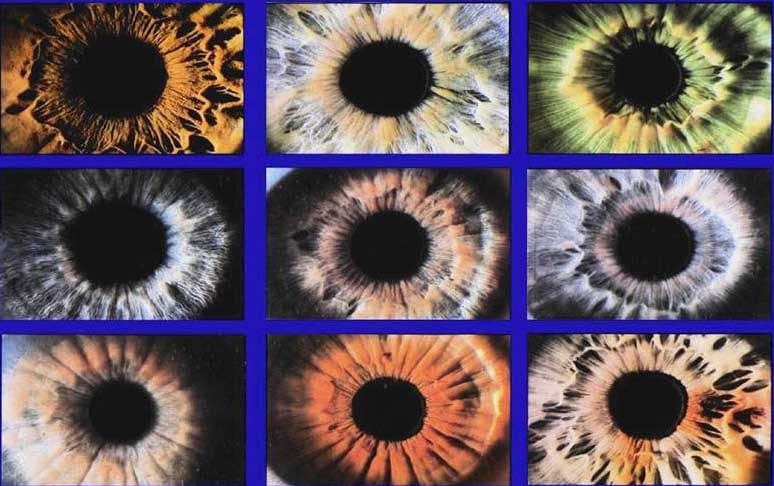

| Every iris is unique |

Iris recognition — currently used worldwide by airports, prisons, laboratories, fitness clubs, hotels and other institutions — is the most accurate biometric available because no two irises are alike, said Etter, a former Deputy Under Secretary of Defense who leads SMU’s Biometrics Engineering Research Group. The technology is challenged, however, by interference when the iris is being scanned, she said. Problems can include glare, eyelashes, eyelids or dim lighting.

With Panoptes, the camera can start with a wide field-of-view at low resolution, find a face, then narrow to the area of interest — the iris. At the same time, Smart-Iris will extend the range of iris acquisition. Instead of one person cooperatively standing motionless with their eye pressed to a scanner, Smart-Iris will make it possible for people to pass through a standard doorway, each one getting their iris scanned — without so much as even pausing — by equipment mounted on walls or door frames. At the same time, the camera would maintain high resolution and more than 150 pixels across the iris.

Easier Smart-Iris scan is unobtrusive, but accurate

That could benefit the Department of Homeland Security. More than 600 million people pass through security to fly aboard commercial airlines each year, according to the agency. Homeland Security relies on the latest technology to monitor more than 700 security checkpoints and 7,000 baggage screening areas.

“Our goal is to develop an iris recognition system that is unobtrusive and accurate. We want to ensure that the right people have access, and that potential intruders are identified, all without impacting flow in high-traffic areas,” said Etter, who directs the Lyle School’s Caruth Institute for Engineering Education.

Into caves and dark alleys

To develop AIM-CAMS, Panoptes is being paired with new off-the-shelf pocket projector technology known as Pico. Pico projectors, often compared in size to a candy bar, make it possible to project digital pictures taken by cell phones and other portable devices onto any wall for large-format viewing.

Combining Pico with Panoptes will allow the low-resolution camera to be used in dark places, such as caves and urban alleys, providing troops with situational awareness, said Christensen, who is chair of the SMU Department of Electrical Engineering and an associate professor.

SMU is collaborating on the research with Santa Clara University in California, Northrop Grumman and Draper Laboratory. Funding came from the Defense Advanced Research Projects Agency, Office of Naval Research and Army Research Laboratory.

Watch a news video about the Panoptes research

Related links:

DOD adds $2 million to SMU’s camera research

Marc Christensen

SMU Profile: Marc Christensen

Conference paper on Panoptes

Department of Electrical Engineering

Bobby B. Lyle School of Engineering